The subsidiary companies of Future City Holding, with the presence of a specialized team of outstanding university graduates and university professors, have successfully achieved Grade 1 recognition from the Housing and Urban Development Organization of Khorasan Razavi Province. They have been active for nearly a decade in various fields including geotechnical engineering, concrete quality control, and technical inspection of welding.

The main activities of the company are as follows:

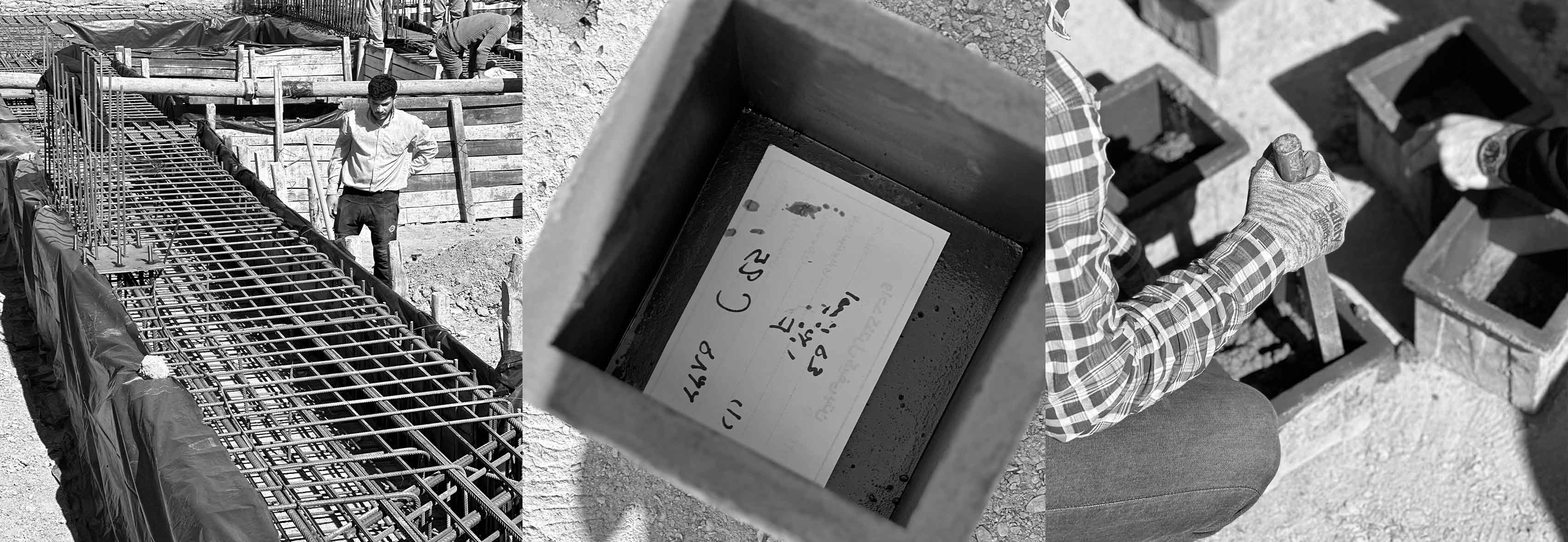

- Conducting geotechnical studies including field tests and sampling.

- Performing specialized soil tests and determining the required parameters for structural load-bearing and design calculations.

- Providing concrete mix designs.

- Determining concrete compressive strength.

- Determining concrete slump and fresh concrete sampling on-site.

- Core sampling of hardened concrete (coring).

- Non-destructive testing using ultrasonic methods.

- Estimating concrete strength using the Schmidt hammer.

- Quality control of constituent materials including cement, aggregates, and water.

- Performing tests such as particle size distribution, specific gravity, abrasion resistance, and moisture content.

- Soil improvement for constructing tall buildings or industrial structures on loose soil.

- Designing and constructing various retaining structures.

- Strengthening foundations against seismic activity and dynamic machinery loads.

- Preventing further settlement of buildings constructed on collapsible soils or inadequate foundations.

- Designing, overseeing, and implementing waterproofing systems for building excavations.

- Conducting all complementary tests such as consolidation, plate load test, Atterberg limits, and more.

- Performing weld non-destructive tests (NDT) according to the percentages specified in the Iranian Structural Welding Code (Publication 228) and AWS-D1.1 standard.

- On-site permanent supervision as needed.

- Qualifying and evaluating welders.

- Reviewing destructive test (DT) results, such as tension, bending, charpy, etc., on raw materials.

- Controlling the quality of materials delivered to the contractor's workshop.

- Controlling the contractor's C Plan and auditing the factors and devices of the contractor's Q.C unit.

- Checking the provided WPS by the contractor and preparing PQR if necessary.

- Monitoring and overseeing cutting operations.

- Monitoring and overseeing fit-up and connection assembly.

- Monitoring and overseeing the welding process before, during, and after welding.

- Monitoring the calibration of welding equipment and the maintenance conditions of electrodes.

- Controlling the manufactured parts and issuing certificates in accordance with the manufactured parts regarding dimensions, thickness, and type of used steel according to the relevant shop drawings.

- Supervising and controlling the sandblasting, painting process, and thickness gauge measurement of paint, as well as issuing quality control certificates.

- Supervising and approving the manufactured parts for transportation and performing the final control of the parts.

- Providing summary reports of daily, weekly, and monthly inspections.

- Conducting tensile and forging tests on rebars in cooperation with the Acruditah Laboratory of the Standards Department.

Please note that this translation is a direct translation of your provided text and might require further refinement to ensure smooth English flow.

Images of the Laboratory Environment

Farsi

Farsi Arabic

Arabic

opinions

4

1401/10/14 22:52:09

نیما اسعدی

عالی بود